E

403 ERROR Request blocked. We can’t connect to the server for this app or website at this time. There might be too much traffic or a configuration error. Try again later, or contact the app or website owner. If you provide content to customers through CloudFront, you can find steps Continue Reading

Coppa Milano Sanremo 2023, la leggendaria corsa

La gara più antica d’Italia. di Carlo De Bernardi Esattamente 117 anni fa, nel 1906, un gruppo di appassionati di automobili, un mezzo che cominciava a farsi vedere lungo le strade polverose degli inizi del secolo, decide di organizzare una gara da Milano verso la Riviera dei Fiori. La scusa Continue Reading

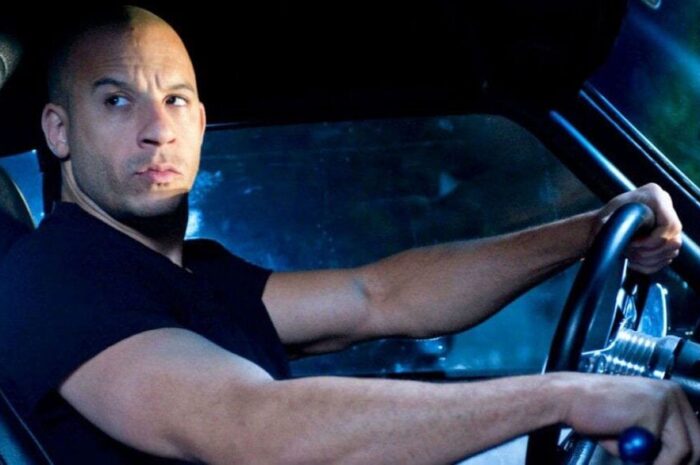

Throwback: When Vin Diesel's Fast & Furious Car Was up for Sale! – Cash Roadster

In 2022, gearheads and avid fans of the “Fast & Furious” film franchise rejoiced. This is because the 1968 Dodge Charger, which Vin Diesel drove during the closing scene of ‘Fast and the Furious 7’ was soon to be auctioned off. Iconic Car Also called the “Maximus the Ultra Charger’, the Dodger Continue Reading

Here's Why this Million Dollar LA Female Broker Decided to Sell Her Mansion for $23.9 Million! – PaydayVille

There comes a time in our life, wherein we have to let go of certain things, especially those that hold heavy sentimental value to us in order to finally move on and start a brand new chapter of our lives. Deal or No Deal? In Tracy Tutor’s case, it is Continue Reading

Experience Luxury Vacation and Sun-Drenched Serenity in the Algarve, Portugal By Shantivillas Group – Truly Classy

Shantivillas Group, a leading luxury holiday villa and apartment rental company in Algarve, Portugal, has been recognized as the Best Luxury Private Pool Villas in Algarve, Portugal, 2023 by Luxury Lifestyle Awards. Founded in 2016, the company offers high-end accommodations and experiences in a region known for its sunny skies year-round, Continue Reading

I migliori ristoranti di Zurigo: una guida curata

Gemme gastronomiche: un’esplorazione delle migliori esperienze culinarie di Zurigo. Nel cuore effervescente dell’Europa, dove la frizzante aria alpina si mescola al trambusto cosmopolita, Zurigo emerge come un paradiso gastronomico. Le sue strade labirintiche, fiancheggiate da un arazzo di fascino antico ed eleganza moderna, custodiscono tesori epicurei nascosti che ti trasportano Continue Reading

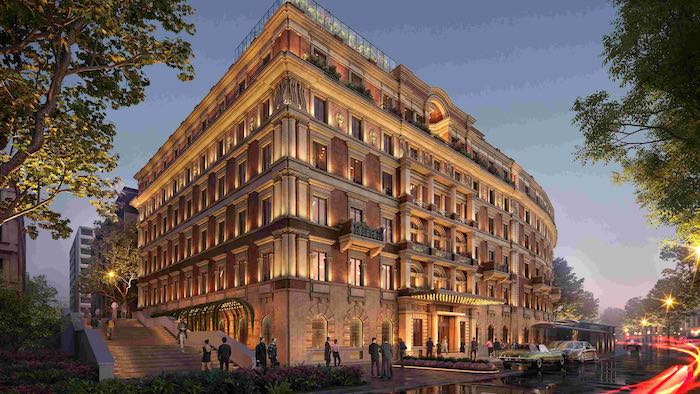

The May Fair Hotel, a London Icon, joins Radisson Collection

The launch coincides with Radisson Collection’s first anniversary since its introduction to the Radisson Hotel Group brand architecture. Edwardian Hotels London and Radisson Hotel Group are also announcing their intention for a 10-year extension to their strategic partnership. Radisson Hotel Group, one of the largest and most dynamic hotel groups Continue Reading

Gozney to launch the UK's most remote restaurant for one day only – Luxuria Lifestyle London

Premium outdoor oven brand Gozney is teaming up with fire-pioneering chef Chris Roberts to launch the UK’s most remote restaurant, a one-of-a-kind pop-up set high on the clifftops of the Jurassic Coast. Gozney is taking its mission to change the way the world cooks outdoors one step further with the Continue Reading

Six Senses CEO Neil Jacobs On Residential Wellness – Lux Magazine

The Whiteley Members Club Neil Jacobs, CEO at Six Senses Neil Jacobs is CEO of the iconic hotel and residencies group, Six Senses. Here, he speaks to Samantha Welsh about the brand’s wellness model LUX: How far are your wellness beliefs rooted in your personal values and lived experience? Neil Continue Reading

InterContinental Rome Ambasciatori Palace, lusso discreto ed elegante

Lusso discreto e mai urlato, ma il glamour e l’eleganza all’hotel InterContinental Rome Ambasciatori Palace sono elementi distintivi ed essenziali. Arriva nella Capitale, dopo un lungo restauro di uno dei palazzi più belli di Via Veneto, un brand dell’hotellerie che punta in alto e regala alla città un nuovo punto Continue Reading